The Ovlac Mini plough is designed to combine the advantages of reduced tillage with soil inversion. Ovlac have listened to the market and utilised their 85 years of manufacturing experience to produce a plough capable of complete inversion without disturbing the soil deeper than 20cm. The result, the Mini shallow plough, is a specialist product enabling high work rates, low fuel consumption and excellent weed control.

THE RIGHT MODEL TO FIT YOUR TRACTOR

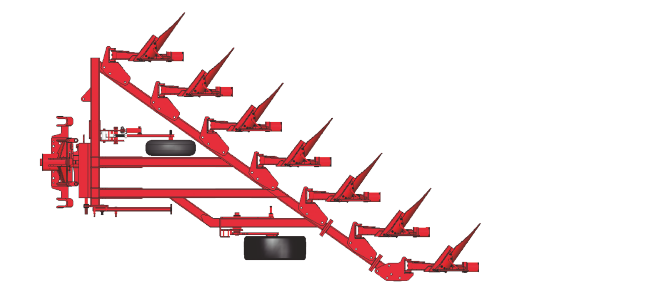

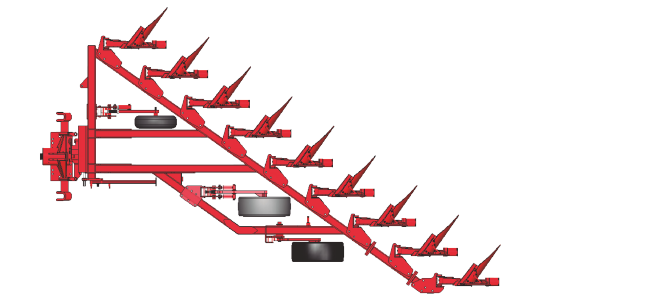

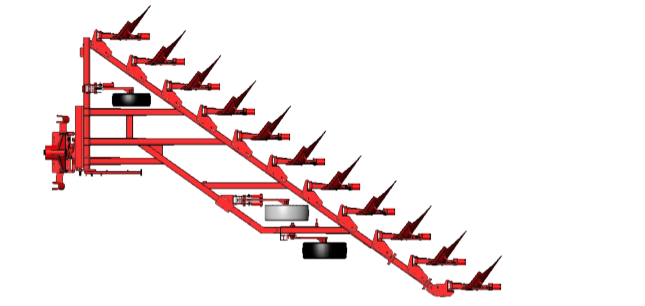

The Mini-N range is based on three main frames.

Mini-N-5, Mini-N-7 and Mini-N-9, which can all be extended with one or two additional bolt-on bodies.

FEATURES AND BENEFITS

PROTECTION SYSTEMS

In order to take different working conditions into account, Ovlac Mini ploughs can be equipped with two alternative protection systems.

SHEARBOLT SYSTEM - NF

The simplest of the two systems. The shearbolt thickness, steel grade and position are calculated so it breaks under a pressure of approx. 2400kg exerted at the plough point. It is imperative that broken shearbolts are replaced with genuine Ovlac bolts. Non-genuine shearbolts with a different dimension or steel grades can result in serious damage to the plough.

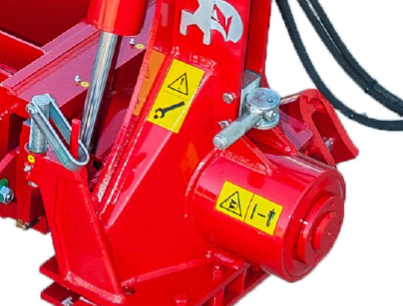

NON-STOP HYDRAULIC RESET SYSTEM - NH

A regulated trip mechanism. This system allows adaptation of release pressure according to soil conditions. In heavy or compacted soil, pressure can be increased in order to guarantee penetration and maintain an optimal working position of the bodies. On the contrary, in stony conditions pressure can be set lower to prevent stones being brought to the surface.

WHEELS

A large range to meet your needs

Ovlac Mini reversible ploughs can be equipped with a number of different wheel types.

There are Depth Control Wheels or Combi Wheels, for depth control and transport.

In addition a depth control wheel can be fitted at the front of the Mini.

This is recommended for larger ploughs (Mini-N-9) as it provides extra stability.

Transport and depth wheel.

Mini N - 340/55 R16

Mini S - 500/50 R17

Front depth control wheel.

Mini N option - 200/60 R14.5

Mini S standard - 250/65 R14.5

3M IVERSET SYSTEM

Unique hydraulic depth control wheel 280/70 utilising 3M Iverset System.

Clips are easily added and removed to adjust the depth.

Quick no-tools depth adjustment.

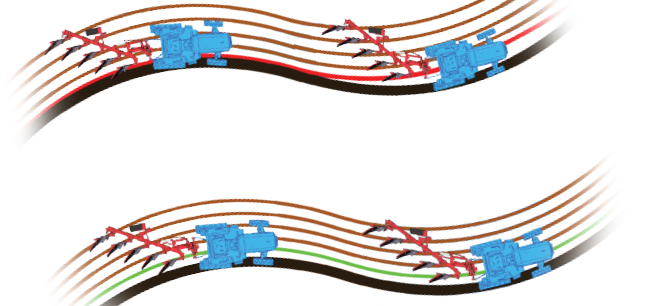

Mode 1

In Mode 1 Ovlac’s hydraulic rear depth wheel allows a gradual start and finish on the headland. This means shorter “in’s and out’s” on the headland and therefore less passes to finish the field.

Mode 2

Set in Mode 2 the hydraulic rear depth wheel controls depth at the edge of the field so operators can plough right up to the field boundary.

(Not applicable on Mini)

Mode 3

Set the wheel in mode 3 to allow it to move freely.

REVERSIBLE MINI N

Ever since the first Mini’s were produced back in 2003, successive improvements and innovations have been steadily implemented thanks to feedback from farmers, from more than 15 countries, alongside Ovlac’s experience. Ovlac listen to their customers who, as professionals, can provide invaluable insight to help improve machines.

Nowadays, the Mini is a shallow plough with an undisputable reputation with regards to both reliability and efficiency - its proven.

SEMI-MOUNTED MINI S

The semi-mounted Mini has been specifically developed for large farms and high-power tractors. Available up to thirteen furrows, the Mini S has a working width up to 5m. Around 3 ha/hr can be ploughed at ease.

The Mini S is based upon the same frame base used for the traditional on-land semi-mounted ploughs.

In order to ease the turnover of the plough at the headland, the Mini S features a front articulation, this folds in the front bodies thus, reducing the turnover radius and minimising the strain on the tractor arms and headstock.

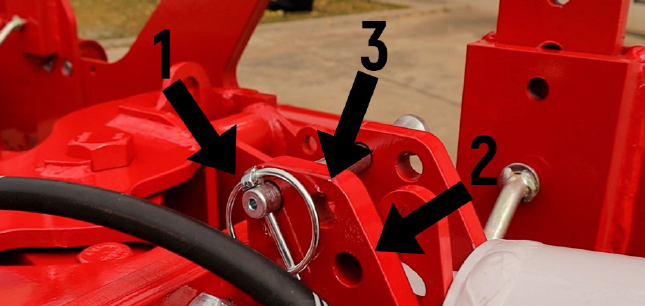

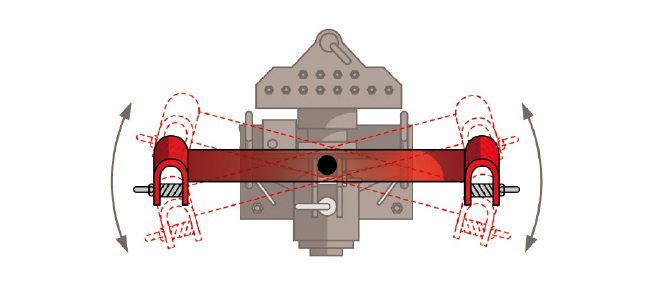

OSCILLATING CROSS SHAFT - AUTOMATIC SELF-ALIGNMENT

Ovlac Mini ploughs are equipped with an Oscillating Cross Shaft with a centre pivot. The plough is pulled from the centre pivot point which ensures it can move independently to follow the tractor and find the perfect balance between the side pressure exerted on the mouldboard and the landslide.

Therefore once the plough is set correctly it is not necessary to make complicated adjustments in order to ensure the plough pulls straight. In work the plough will follow the tractor perfectly.

When lifting the plough for transport or turn over, the Oscillating Cross Shaft automatically locks itself in the central position.

The cross shaft movement also makes it very easy to hitch up to the plough. In addition to the operational benefits the Oscillating Cross Shaft significantly reduces strain on the whole plough and fuel usage.

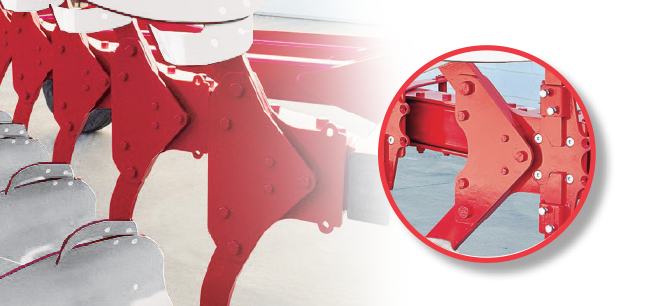

BOLT ON LEG BRACKETS

The Hardox 500 legs are bolted on to the frame therefore if the worst happens and one is damaged it can be easily replaced.

- SUBSTANTIAL, SIMPLE AND RELIABLE MAIN FRAME

The Mini is designed for simplicity, reliability and operator friendliness.

It is extremely easy to adjust and very reliable.

All the main parts (headstock, frame and legs) are robot welded for longevity.

NON STOP PLOUGHS FOR THE HARDEST CONDITIONS

The 3D articulated Security Rod linking the leg holder to the main frame has been designed to withstand the most rigorous conditions. It provides protection from sideways and vertical force as well as enabling break-back.

HYDRAULIC FRONT FURROW ADJUSTMENT

The Mini N and S have Hydraulic first furrow adjustment as standard. This makes it possible to adjust the plough offset to match the tractor width. Once set it can easily be varied from the tractor seat to get closer to or further away from the furrow if the working conditions require, for example on hillsides.

MINI PLOUGH MODELS

OPTIONS AND ACCESSORIES

A wide range of accessories are available in order to adapt the plough to all soil types and working conditions.

Slatted mouldboards for sticky conditions-Trashboards to improve burial of trash

Extra large forged share. 12cm longer than standard share

Eco Flow share, advised for sticky soils to improve flow

1st furrow hydraulic width adjustment

(Standard in the UK)

In-the-furrow version

(only for Mini-N-5 and 5+1)

Inner depth control wheel

(available for Mini-N 7 and 9 frames)

Additional bolt-on bodies

Additional landslide wear plate. Reduces main landslide wear and therefore running costs

(STANDARD IN THE UK)

“Pan-Cracker”

Light kit

Headstock lock for transport

Share via WhatsApp

Share via WhatsApp